Understanding the Role of Suspension Control Units in Vehicle Performance

4 Jun

2025

Highlights:

- Introduction

- Auto-adjusts suspension for smooth rides

- Fits all vehicle types, including EVs

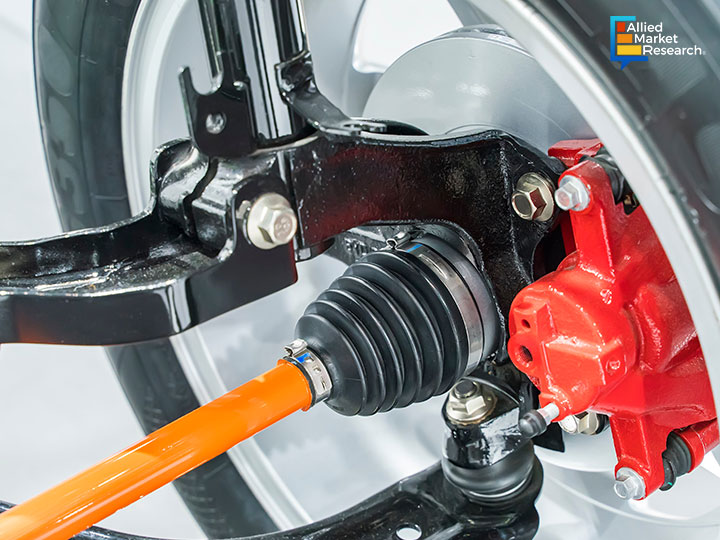

Suspension control units play an important role in modern vehicles. These electronic units help manage how a vehicle responds to different road conditions. By adjusting the suspension system in real time, they improve ride comfort, stability, and overall handling. These units are now being used across many types of vehicles, from luxury cars to commercial trucks and even electric vehicles.

What a Suspension Control Unit Actually Does

A suspension control unit is a part of a vehicle’s electronic control system. It collects data from sensors and makes quick decisions to adjust the suspension. These adjustments happen automatically, based on how fast the vehicle is going, the type of road, or how the driver is steering or braking.

For example, if a car is moving quickly over a bumpy road, the control unit will make the suspension stiffer or softer in real time to keep the ride smooth and safe. In some advanced systems, these changes happen every few milliseconds. This kind of control reduces body roll during sharp turns, lowers braking distance, and improves how tires stay in contact with the road.

Use across Different Vehicle Types

In the past, these systems were mostly found in high-end luxury cars. But now, they are being added to SUVs, pickup trucks, sports cars, and commercial vehicles. As safety and comfort continue to matter more, more vehicle makers are adding these systems as standard or optional features.

Electric vehicles also benefit from suspension control units. Since EVs have a different weight distribution due to the battery, their suspension needs careful tuning. Control units help manage the extra weight and deliver a better driving experience. Some models also use them to adjust the vehicle height to reduce drag and improve energy efficiency. The suspension control unit industry is expected to gather a revenue of $31.4 billion by 2033. The market accounted for $16.7 billion in 2023 and is projected to rise at a CAGR of 6.9% during 2024-2033.

How the Software Supports the Hardware

The software inside the suspension control unit is just as important as the hardware. It needs to read input from multiple sensors and respond within fractions of a second. The algorithms handle data like vehicle speed, wheel movement, braking, and even weather if external sources are used.

Vehicle makers often team up with software suppliers to build these algorithms. The software also undergoes testing and certification before use. As vehicles get more connected and software-driven, the control unit will take on a bigger role in shaping suspension system design.

Recent Industry Activity

In April 2025, Continental AG introduced its new semi-active suspension system with a built-in control unit aimed at mid-size commercial vehicles. The company highlighted how this system helps improve fuel efficiency and stability without needing full air suspension. This development shows how electronic control can be applied beyond luxury vehicles and into more practical use cases.

Another update came from ZF Group earlier this year. It announced the expansion of its production line for chassis electronics in Hungary. This includes suspension control units designed for both electric and hybrid vehicles. The move reflects rising demand from European automakers seeking reliable and scalable control systems.

Challenges in Integration and Testing

Even though these control units offer many benefits, integrating them into different vehicle platforms takes effort. The unit needs to be tested with the rest of the vehicle’s control systems. Engineers must also ensure it works well with different suspension setups—such as air suspension, hydraulic systems, or traditional spring-based systems.

Testing often includes simulations, road tests, and lab-based evaluations. This takes time and requires partnerships between vehicle manufacturers, parts suppliers, and software developers. As vehicles become more complex, the time needed to fully integrate and test these systems also increases.

Use in Fleet and Commercial Vehicles

More fleet operators are exploring vehicles that include active suspension systems. For delivery vans and long-haul trucks, better suspension can reduce wear on the vehicle and improve driver comfort. Since suspension control units can help reduce damage from bad roads and carry heavy loads more efficiently, they are gaining attention in fleet management discussions.

Some fleet managers are also looking at how data from these control units can be used for maintenance. If a unit detects unusual suspension behavior, it could alert the operator to a possible issue before it becomes a serious problem.

Connections With ADAS and Autonomous Driving

With more vehicles including advanced driver assistance systems (ADAS), the suspension control unit has become part of the larger driving experience. Systems like lane-keeping, adaptive cruise control, and self-parking rely on stable vehicle performance. And, responsive suspensions are making these features more effective and reliable.

In test vehicles that are moving toward higher levels of autonomy, the suspension control unit also helps reduce discomfort for passengers. Since there may not always be an active driver adjusting to the road, the suspension needs to do more of the work automatically. Engineers are studying how these systems can work alongside sensors like lidar and radar to deliver smoother and safer autonomous driving.

Summing up

Suspension control units are becoming a key part of how vehicles operate, not just in high-end cars but across all segments. They are helping improve safety, comfort, and vehicle durability. With steady progress in hardware, software, and industry partnerships, these systems are likely to be part of every major vehicle platform where ride quality and control matter.

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training