Can Reciprocating Compressors Equip Your Business with Versatile and Sustainable Solutions?

27 Feb

2024

Highlights:

- Various types of reciprocating compressors

- Reasons behind the growing demand for these compressors

- Emerson’s innovation

- Some key acquisitions in the sector

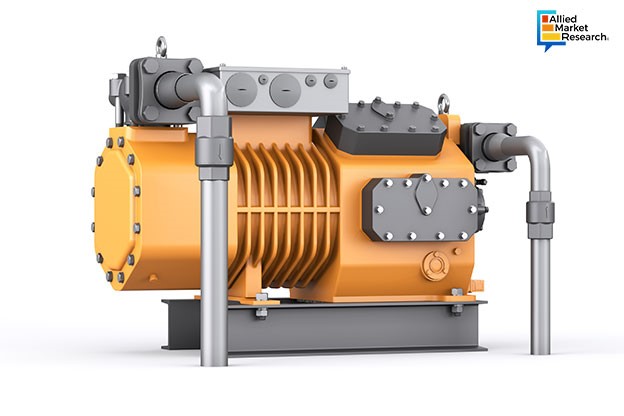

Designed for intermittent duty applications in harsh environments, a reciprocating compressor, also known as a piston-type air compressor, is used across various industrial settings where compressed air is needed. It is a mechanical device comprising of a piston driven by a canker shaft in a cylinder. The device is used to offer compressed air by undergoing a cycle of operations. It comes under the category of positive displacement compressors that operate by drawing air in through the suction valves, creating a vacuum, and then the piston inside the cylinders moves in a reciprocating motion to begin the compression. Once the pressure inside the cylinder is higher than the pressure in the discharge pipe, the air is released into the discharge tank through the discharge valve. In this article, we are going to discuss various types of reciprocating compressors promoting various industrial applications.

Which types of reciprocating compressors enhance your business performance?

The reciprocating compressors are of three types – single-acting, double-acting, and diaphragm. In single-acting air compressors, the compression of air takes place on only one side of the piston, which means that the air is compressed during one stroke of the piston. These compressors consist of only one cylinder in which the initial movement of the piston sucks in the air, and the second movement compresses the air. These types of compressors are used for small to medium-sized industrial applications, refrigeration systems, and pneumatic tools.

However, in double-acting compressors, air compression takes place on both sides of the pistons. These compressors consist of two cylinders. In the first cylinder, the air is partially compressed and then pushed into the second cylinder. After that, the air in the second cylinder is further compressed before being moved to the storage tank. Such types of air compressors are widely used in heavy-duty industrial applications such as gas pipelines, processing plants, and petrochemical & chemical industries that require high efficiency. Owing to its wide applicability, the double-acting compressor segment is expected to hold the major industry share by generating a revenue of $984.9 million during 2023-2032.

On the contrary, diaphragm compressors use diaphragms instead of pistons to carry out air compression. These compressors are used to handle toxic and corrosive gases in the chemical industry. Owing to their effective air compression, such compressors are widely used in pharmaceutical and laboratory applications.

Why are reciprocating air compressors highly in demand across industries?

Unlike other types of positive displacement compressors such as rotary screw compressors, the reciprocating air compressors produce high-pressure gases up to 30,000 PSI. They are used for various climate control applications, requiring 60-90 PSI. This implies that such types of air compressors are used for flexible uses. Moreover, these types of compressors are available in both oil-flooded and oil-free varieties. Users place such types of air compressors according to their flexibility and use. They are placed at the top or bottom, offering convenience and suitability to various industrial applications.

Furthermore, reciprocating compressors are highly energy efficient. They produce high-pressure gases using less energy. This feature of such types of compressors makes them ideal for applications where an intermittent supply of compressed air is required rather than a continuous supply. In addition, relying on these piston-type air compressors is advantageous to industries. They offer greater durability and lower maintenance costs. The machines using these compressors do not require frequent replacement and upgradation.

Emerson’s New CO2 Semi-Hermetic Reciprocating Compressor

In March 2023, Emerson, a leading U.S.-based manufacturer of engineering products announced the launch of its new Copeland Transcritical CO2 (R744) semi-hermetic reciprocating compressor that offers the largest displacement. According to the company, these compressors can be standard medium-temperature compressors that can offer greater design flexibility and significantly reduce the number of compressors needed on a transcritical CO2 rack. This newly designed compressor can offer lower sound and vibration across the operating envelope. Recently, the Vice President of End Users at Emerson Commercial & Residential Solutions said that the U.S. refrigeration market has increased the use of CO2 (R744), stepping ahead toward sustainability and regulatory compliance goals.

Recent acquisitions that your business should look into

Many leading players in the reciprocating compressor industry have undergone a series of acquisitions to augment the competitive landscape. For instance, in November 2023, Cooper Machinery Services, a global leader in the supply of after-sale services, announced the acquisition of Terrecorp, a manufacturer of aluminum, bronze, and steel-backed bearing shells. With this acquisition, Cooper Machinery Services aims to enhance its product portfolio and services by offering a large installation base of engine compressors that use emission-reduction technologies.

Similarly, in March 2023, Danfoss, a Danish multinational company announced its acquisition of BOCK GmbH, a leading manufacturer of compressors and condensing units for stationary and mobile refrigeration and air-conditioning. This acquisition is expected to help Danfoss strengthen its compressor portfolio by providing greener cooling and heating solutions by using BOCK’s best-in-class technology. With this agreement, Danfoss aims to expand its portfolio by offering compressors, exchangers, controls, and valves, accelerating the production of energy-efficient solutions, and driving the world toward natural & low-GWP refrigerants.

To conclude, the surge in demand for reciprocating compressors from storage plants and refineries is anticipated to create extensive opportunities for the sector in the coming years. Moreover, the rise in the use of air compressors in the oil and mining industries is expected to push the sector toward achieving new heights in the future.

To identify emerging trends and opportunities in the reciprocating compressor industry, feel free to talk to our industry experts today! They can also help you make informed business decisions about pricing, margin, supplier selections, distribution channels, and new product development.

Rosy Behera

Author's Bio- Rosy Behera holds a bachelor’s degree in Electrical and Electronics Engineering and now she is a content writer by profession. She loves to portray her thoughts and ideas with a nice command of words. Grabbing an audience with her creative write-ups is one of her biggest assets so far. Apart from writing, she is a certified “Odisi” dancer and has done Gardharva in Drawing, Painting, and Arts. She always explores new things through travel and is a big foodie.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training