Advanced Fiber Optic Preform Trends Have Revolutionized Semiconductor Businesses

9 May

2024

Highlights

- Introduction

- Trends in the fiber optic preform industry

- Expansion of Asia-Pacific fiber optic preform sector

- Recent developments in the sector

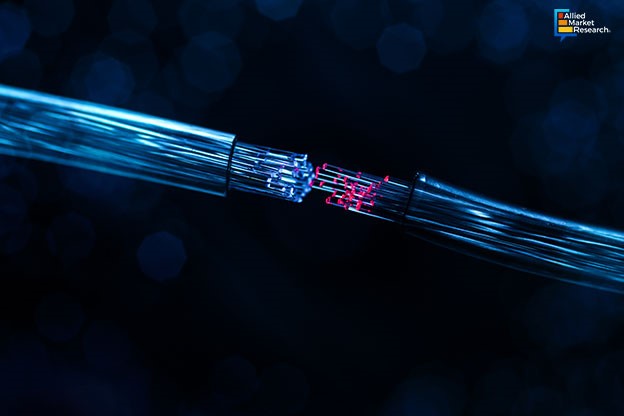

Fiber optic preforms are the core units required for the construction of fiber optic cables and are vital for the functionality of the global communications infrastructure. Their primary applications include illumination, light transmission, flexible bundling, and laser delivery systems. Glass filaments are used in fiber optic preforms due to their advantages in deep molding and for items with uncertain structural properties. The production process of optical fiber preforms includes designing high-purity cylindrical glass, which is then drawn into slender fibers capable of transmitting data over extensive distances at the speed of light.

Fiber optic preforms are mainly categorized into single-mode fiber optic and multi-mode fiber optic. Single-mode fiber optic features a reduced core diameter, enabling the transmission of only a single mode of light. As a result, this minimizes signal dispersion and attenuation by empowering single-mode fiber optics to transmit data over greater distances in contrast to multi-mode fiber. The exceptional transmission abilities, expanded bandwidth, and adaptability to emerging high-speed technologies have established single-mode fiber optic cables as the predominant choice in fiber optic usage. Owing to these factors, the single-mode fiber optics segment is expected to generate an absolute revenue of $4,704.95 million during the forecast period.

Advanced fiber optic preforms trends have changed the outlook of the industry

5G integration

The advent of 5G technology and the expectation of upcoming communication standards fuel substantial advancements in optical fiber perform manufacturing. The next generation of mobile networks necessitates extensive fiber optic infrastructure to accommodate connectivity requirements and elevated data volumes. As a result, preform manufacturers innovate products suitable to these new technologies, guaranteeing that optical fiber accommodates higher frequencies and broader bandwidths essential for 5G and beyond.

Automation of fiber optic preform production

Automation has progressively gained traction in optical fiber preform manufacturing to improve efficiency and uniformity. Automated systems monitor fiber optic testing, the drawing process, material deposition, and initial inspection phases. This monitoring facilitates more production and ensures the consistent production of high-quality fibers, essential for sustaining the performance of optical networks.

Enhanced fabrication techniques

Advancements in the manufacturing methods of optical fiber preforms, including techniques such as MCVD (Modified Chemical Vapor Deposition) and PCVD (Plasma Activated Chemical Vapor Deposition), enhance production efficiency and scalability. These improvements lower production expenses & time requirements and boost the consistency & symmetry of preforms. Continuous refinement of these methods is essential to meet the surge in demand for fiber optic cables.

The Asia-Pacific sector dominates the fiber optic preform sector

Prominent organizations and governmental bodies across the Asia-Pacific region have made substantial investments to advance fiber optics preform technology. This concerted effort has fueled the expansion of the fiber optics preform industry in the region. Among emerging economies in Asia-Pacific, South Korea is projected to display a notable CAGR of 12.65% by 2032. The growth of fiber optic preform industry across South Korea is attributed to strategic investments in telecommunications, supportive government policies, and technological leadership.

Top entities have implemented novel strategies to thrive in the competitive industry

Frontrunners in the global fiber optic preform industry have adopted strategic alliances to strengthen their position in the evolving sector. These strategies include partnerships, collaborations, acquisitions, mergers, investments in R&D, and new product launches. For instance, Yangtze Optical Fiber and Cable invested in establishing a production base for communication optical cables in October 2023. This strategic move aims to provide residents with access to superior product solutions by enhancing the reliability and stability of communication experiences.

On the other hand, in June 2023, a broadband service and application provider, TruVista formed a partnership with STL, to accelerate the expansion and improvement of South Carolina's rural connectivity infrastructure. Both companies made substantial investments in manufacturing and constructing fiber networks.

To sum up, the primary applications of fiber optic preform include illumination, light transmission, flexible bundling, and laser delivery systems. Moreover, single-mode fiber optics has gained popularity due to its expanded bandwidth, adaptability to emerging high-speed technologies, and exceptional transmission abilities. Top players discover new products to sustain the dynamic industry.

Contact our experts to gain a competitive analysis of the global fiber optic preform industry.

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training