How Are Hydraulic and Electric Linear Actuators Promoting Energy Efficiency in the Aerospace Industry?

10 Aug

2024

Highlights:

- Introduction

- Power-to-weight ratio, performance, and power transmission

- Operation, maintenance, and precision

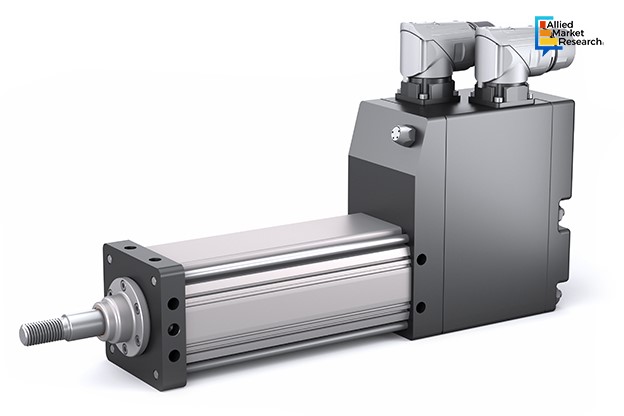

Hydraulic actuators utilize pressurized fluid to produce linear motion. They are renowned for their ability to generate high force and operate reliably under extreme conditions, making them indispensable in aerospace applications. Electric linear actuators, on the other hand, use electric motors to produce linear motion and are increasingly being adopted in aerospace applications due to their energy efficiency and precision. These actuators improve energy efficiency, and their evolving technologies restructure how energy is managed in aircraft and spacecraft. The systems also provide smooth and precise control over motion, which is the key in exact positioning and force control. Moreover, they are robust and can withstand harsh environmental conditions, making them suitable for demanding industrial applications like aerospace.

High power-to-weight ratio, strong performance, and efficient power transmission

Aerospace applications often require actuators that can handle high loads and extreme conditions. Hydraulic actuators are used in flight control systems, landing gear, and cargo handling. Advances in hydraulic technology, such as the development of lightweight materials and modified fluid dynamics. Their reliability assures consistent performance without frequent maintenance or failures, minimizing the need for energy-consuming repairs and system downtimes. Moreover, these actuators transmit power efficiently through pressurized fluids which allows for precise control of mechanical movements. Furthermore, they provide substantial force output relative to their size, where weight saving is the key. This output controls large flight surfaces, such as wing flaps and landing gear, where significant forces are required.

Safran, a leading global aerospace supplier, announced to acquire Collins Aerospace’s actuation and flight control business in July 2023. This strategic move aims to enhance Safran’s capabilities in hydraulic actuators and flight control systems, which are critical for precise control of large flight surfaces like wing flaps and landing gear. The acquisition consolidates Safran’s position in the aerospace market, allowing it to leverage advanced technology and innovation from Collins Aerospace to improve efficiency, performance, and weight savings in hydraulic systems.

NASA’s research into lightweight hydraulic components, such as CFRP actuators, has demonstrated a 10-15% reduction in weight and a corresponding improvement in fuel efficiency. For example, using CFRP components in the Boeing 787 Dreamliner’s landing gear contributed to a 3% reduction in fuel consumption. In March 2016, Boeing and Parker Hannifin, a global leader in motion and control technologies, partnered to advance hydraulic systems for aerospace applications. They focused on the betterment of hydraulic components’ performance and reliability used in Boeing's aircraft, particularly in extreme environments such as high altitudes and varying temperatures. Advancements in aerospace technology, increasing demand for precision in manufacturing, and the preference for energy savings have boosted the growth of the hydraulic and electric linear actuators industry which is expected to generate a revenue of $118.2 billion by 2032.

On-demand operation, reduced weight and maintenance, and precision

Electric linear actuators are used in aerospace for applications such as cabin pressure control and auxiliary power units. They reduce the aircraft's overall energy consumption and increase fuel efficiency. They use electric motors to produce linear motion and are increasingly being adopted in aerospace applications due to their energy efficiency and precision. This on-demand operation results in lower energy consumption and reduced waste. For instance, in an aircraft’s flight control system, electric actuators can provide precise adjustments only when required, enhancing overall energy efficiency. In June 2018, Airbus and Safran, a leading aerospace supplier, collaborated to develop and implement electric linear actuators in their aircraft systems. It focused on integrating advanced electric actuator technology into Airbus's commercial aircraft to enhance performance and reduce service requirements.

Furthermore, electric linear actuators remove the need for hydraulic fluids, pumps, and complex plumbing systems. Lighter systems contribute to fuel savings and improved energy efficiency. Moreover, precise control over landing gear deployment can enhance aerodynamic efficiency and minimize drag. According to Airbus, the use of electric actuators in the A350 XWB’s wing systems contributes to a reduction in fuel consumption by up to 2% compared to conventional hydraulic systems. Moog Inc. collaborated with Boeing in February 2020 to integrate advanced electric linear actuators into Boeing’s next-generation aircraft designs using Moog’s expertise in electric actuation technology. The Boeing 787 Dreamliner, which utilizes electric linear actuators in its wing and landing gear systems, benefits from a weight reduction of about 1,500 kg (3,300 lbs) per aircraft due to the elimination of hydraulic components. This weight saving is critical for enhancing overall aircraft performance.

To sum up, hydraulic actuators excel in high-force applications, and electric linear actuators offer superior efficiency, precision, and low services. Cutting-edge technologies like smart control systems, energy recovery, and advanced materials are projected to upgrade both types of actuators. Their integration with renewable energy sources and AI-driven control systems is anticipated to further improve their energy efficiency, driving sustainable development across sectors. Aerospace companies can thus fulfil their objectives of saving energy, reducing operational costs and in the long run, and build a sustainable, and flourishing industry framework.

To identify market trends and future revenue prospects of the hydraulic and electric linear actuators industry, reach out to our analysts, now!

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training