New Generation of Honeycomb Sandwich Materials to be Cheaper & Efficient

20 May

2016

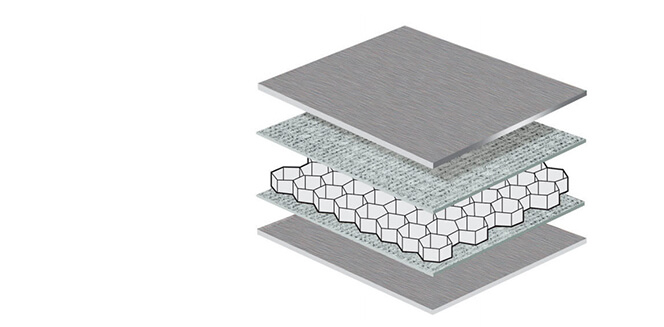

Honeycomb sandwich material is a three-layer structure, in which a low-density core material shaped in honeycomb is inserted between two layers. With the help of honeycomb structure, high strength, stiffness, corrosive resistance, and reduction in weight is achieved.

EconCore's new generation of aluminum composites panels:

A thick layer of polymer is inserted in between two layers of aluminum sheets to manufacture a honeycomb sandwich material. EconCore technology has developed panels to replace the thick layer with a thermoplastic honeycomb core. Thermoplastic ThermHex honeycomb core is combined with aluminum skins to lower the weight of the material by 50%. Moreover, it is a cheaper and offers enhanced efficiency. As the combination of metal skins and thermoplastics have cost and efficiency benefits, TATA Steel launched production of steel cladded honeycomb panel in collaboration with EconCore. This product, known as Coretinium, would be suitable for European building and transportation industries. Coretinium is light weight, provides insulation, and manufactured using minimal resources.

Read more details of the report at: https://www.alliedmarketresearch.com/honeycomb-sandwich-material-market

Honeycomb Sandwich Material Types:

• Aluminum honeycomb core:

Aluminum honeycomb is a light weight and eco-friendly material having mechanical properties, such as corrosion resistance, stiffness, and fire resistance. It is used in airflow ventilators, automotive machines, laminar flow ventilation, and a crash absorber for kinetic energy.

• Stainless steel honeycomb core:

Adhesively-bonded stainless steel honeycomb cores are cost-effective as compared to conventional welded stainless steel cores. Mechanical properties include moisture & corrosion resistance, flame resistance, and fungi resistance. It is used in bulkheads, joiner panels, and train doors & floors.

• Thermoplastic honeycomb core:

Thermoplastic honeycomb is smaller in size with higher densities with excellent dielectric properties and features including fire, fungi, and corrosion resistance. Applications include wind tunnels, skylights, antennae, energy absorbing structures, filtration media, and EMI/RFI shielding.

EconCore collaborates with DuPont:

In order to provide tough, resilient, and light weight honeycomb sandwich material, EconCore has collaborated with DuPont. A wide array of polymers of DuPont can be utilized to manufacture high-temperature-resistant and durable honeycomb cores by DuPont. Zytel nylon resin and Surlyn ionomer resin materials have been successfully transformed to deliver high performance. “The patented continuous process to make light, rigid and strong cores really enable us to deliver unique possibilities to our customers,” said Fabrice Giaume, technical programs leader for DuPont Vizilon thermoplastic composite at the DuPont European technical center in Geneva.

Wafers made of a light weight, continuously reinforced fiber composite sheet, Vizilon thermoplastic composite, are combined with honeycomb cores. This composite sheet is made up of a heat-stabilized polyamide matrix. With the help of these composite sheets, honeycomb core can optimize their stiffness and strength without increase in weight. “EconCore’s ThermHex technology for continuous production of sandwich panels with thermoplastic honeycomb core has proven to be capable of delivering high-performance sandwich panels at high efficiency and cost levels not achievable for conventional methods,” said Tomasz Czarnecki, technology manager at EconCore N.V. Giaume added that DuPont is looking forward to manufacturing honeycomb panels with dissimilar materials. Skin-core combination offers a wide range of applications with the help of EconCore continuous process with special high-temperature thermoplastic adhesives, such as DuPont Elvamide.

A report published on the honeycomb sandwich material market states that the market would reach $760.1 million by 2022 and expected to register a CAGR of 10% from 2016 to 2022. Analysts studying the industry have presented an exhaustive analysis of market dynamics, detailed segmentation, SWOT analysis of key manufacturers, and competitive scenario.

Akhilesh Prabhugaonkar

Author's Bio- Akhilesh Prabhugaonkar holds a bachelor’s degree in Electronics Engineering from the reputed Vishwakarma Institute of Technology. He has a special interest in the fields of forensics, world history, international relations and foreign policy, sports, agriculture, astronomy, security, and oceanography. An ardent bibliophile and melophile, Akhilesh loves to write on topics of his interest and various other societal issues. This love for writing made him enter the professional world of content writing and pursue his career in this direction.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training