Pressure-Sensitive Adhesives: How They Shape Modern Industrial Applications

9 Jun

2025

Highlights:

- Introduction

- Versatile use

- Innovation & sustainability

Pressure-sensitive adhesives, often called PSAs, are special types of adhesives that stick to surfaces with only a light touch. They don’t need heat, water, or any chemical reaction to form a bond. This simple but effective bonding method is widely used in industries like packaging, healthcare, automotive, and electronics. The strength of PSAs lies in their ability to balance two opposite forces—sticking to a surface and holding themselves together without breaking apart. This balance is what makes them so useful in a range of everyday and specialized products.

Material Innovations Supporting Diverse NeedsThe development of PSAs has gone far beyond the basics. Different materials are used to suit different applications, and some recent innovations have made these adhesives even more adaptable. Silicone-based PSAs are often used in the medical field. They’re soft, don’t harm the skin, and can stay stable even in high temperatures. In contrast, polyurethane-based PSAs have gained attention for being cost-effective and breathable, which is helpful for long-term use on skin, especially in healthcare.

Another interesting development is the rise of hydrogel adhesives. These are gentle on the skin but still offer strong bonding, making them ideal for medical patches and wearable sensors. Some PSAs are now even made with biodegradable materials to address environmental concerns. These newer adhesives break down naturally over time, reducing long-term waste. A particularly advanced type of PSA includes smart tapes. These are used in healthcare devices where the adhesive itself can help track a patient’s condition by including sensors that monitor health data. The pressure sensitive adhesives industry is expected to generate revenue of $17.6 billion by 2030. The market accounted for $9.8 billion in 2020 and is projected to rise at a CAGR of 6.1% during 2021-2030.

Expanding Use across Key IndustriesOne of the biggest areas where PSAs are making an impact is in the healthcare industry. They are used in wound care, surgical applications, and wearable devices. For these uses, the adhesives need to be breathable and comfortable while still holding well over time. Silicone and hydrogel adhesives meet these needs well, offering a gentle touch on sensitive skin.

In the packaging industry, PSAs help in sealing boxes and labels quickly and securely. Because these adhesives don’t require heat or drying time, they make the packaging process faster and more efficient. Their instant bonding feature is particularly useful in large-scale operations that handle high volumes.

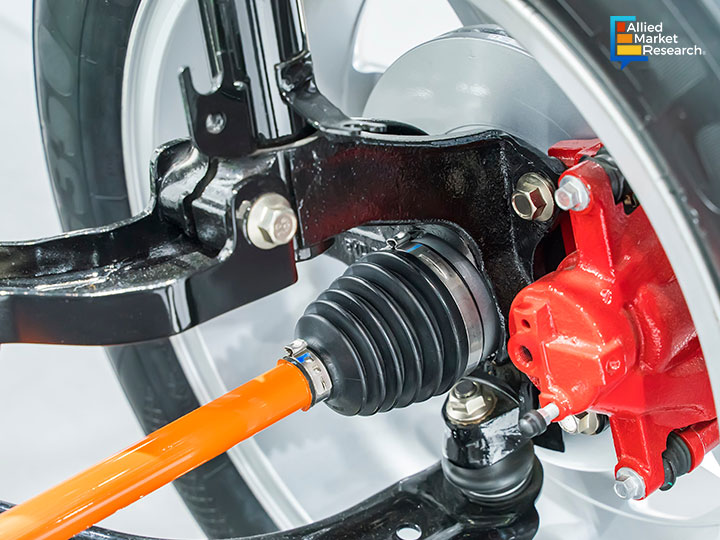

Automotive applications also rely on PSAs for both functional and design purposes. Adhesives are used inside vehicles to attach various components without drilling or welding, which can damage materials or create weak points. These adhesives need to hold up under changing temperatures and vibration, especially when vehicles are in motion or exposed to different weather conditions.

In electronics, PSAs are used to attach lightweight parts and components. Since devices are getting smaller and lighter, adhesives should be thin yet strong. PSAs are perfect for this, helping manufacturers create sleek and compact devices without compromising on strength or safety.

Shifts in Industry and Sustainability FocusThe adhesive industry has seen some important recent changes. Large companies are refining their focus to improve how these adhesives are made and used. For example, new silicone tapes are being developed for long-term medical monitoring, helping make healthcare more comfortable and reliable for patients. At the same time, people are focusing on making operations easier and spending more effort on researching better materials.

Sustainability is also becoming a strong priority. With more industries committing to reducing environmental impact, bio-based PSAs are being introduced. These are made from natural sources instead of petroleum-based materials. These adhesives are still getting stronger and more durable, but they already help make production and disposal cleaner.

Continuous Change and Growing UtilityPressure-sensitive adhesives are evolving in how they’re made and where they’re used. Whether it’s sticking a medical patch to skin or holding an electronic part in place, PSAs are quietly performing tasks that are essential but often go unnoticed. Their ability to adapt to specific needs—whether soft and breathable for skin, or strong and weather-resistant for cars—makes them an essential component in modern manufacturing and design.

With more focus on safety, quality, and the environment, these adhesives are expected to work better while keeping things simple. With industries adjusting their needs, PSAs are evolving to meet their needs with ease, trustworthiness, and new ideas.

For detailed information on the investment opportunities in the industry, contact our specialists here!

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training