Concrete Fiber: Advantages In Construction And Major Types

9 Feb

2022

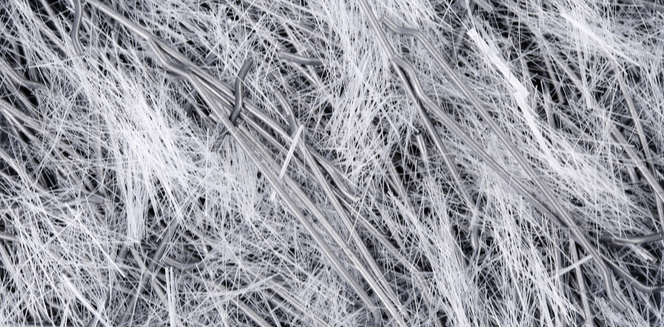

Concrete fiber or fiber-reinforced concrete refers to a mixture of cement, mortar, and discontinuous fiber material. Fibers are used in the concrete to prevent or manage to crack owing to drying shrinkage or plastic shrinkage/ Moreover, they help minimize the permeability of concrete and bleeding of water.

According to Allied Market Research, the concrete fiber market is expected to reach $4.1 billion by 2030, growing at a CAGR of 2021 to 2030. Surge in the use of concrete fiber in building & construction, as well as mining & tunnel applications and increase in use of reinforced in industrial application, drive the market growth.

Advantages of concrete fiber

- It is commonly used where high tensile strength is required. Moreover, it is used to reduce cracking when traditional reinforcement is hard to used.

- It enhances the impact strength and offers higher strain capacity of composite material by limiting the crack growth.

- During industrial projects, the macro-synthetic fibers are utilized to enhance the durability of concrete. As concrete fibers are made from synthetic materials, they are long and thick and can be used to replace fabric reinforcement.

- Concrete fiber has high freeze-thaw resistance that helps in keeping concrete strong for a long period.

- It minimizes steel reinforcement needs

- It can control crack widths which in turn enhances durability.

Major types of concrete fiber

Some major types of concrete fiber are available in a variety of shapes and sizes. The prime differential factor is water-cement ration, diameter and length of fibers, and percentage of fibers.

- Steel fiber reinforced concrete

Some amount of steel fiber in the concrete leads to major qualitative changes in the physical properties of concrete. It can increase resistance to impact, cracking, bending, fatigue significantly. Moreover, it can enhance the long-term behavior of concrete and improve durability, strength, stress resistance, and toughness.

- Polypropylene Fiber Reinforced (PFR) Concrete

It is also called as polypropene and is a synthetic fiber. These fibers can help control cracking owing to plastic or drying shrinkage. Moreover, they help in reducing the concrete’s permeability which in turn reduces bleeding of water. PFR concrete is non-polar and partially crystalline. It shows almost similar properties as polyethylene however it is heat resistant and harder.

- Glass Fiber Reinforced Concrete

It consists of several fine fibers of glass. Glass concrete fiber has somewhat similar mechanical properties to other fibers including carbon fiber and polymers. Glass concrete fiber is used for several polymer products as it is strong and lightweight. In addition, glass concrete fiber contains no air or gas. Thus, it is a much denser.

- Polyester fibers

These fibers are used in concrete fiber for warehouse floors and industrial floors as well as overlays, pavements, and precast products. Polyester fibers provide enhanced resistance to plastic shrinkage cracks and offer toughness. Moreover, if properly designed, it can offer structural capacity as well.

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

After Food & Beverages, Industrial Salt Emerges as a Preservative for Plant Based Cannabis

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training