How Can Adopting the Latest Rubber Testing Equipment Technologies Build Your Brand Image?

7 Feb

2024

Highlights:

- Rubber testing equipment

- Recent trends in the industry

- Technological advancements in the sector

- Recent progressions in the industry

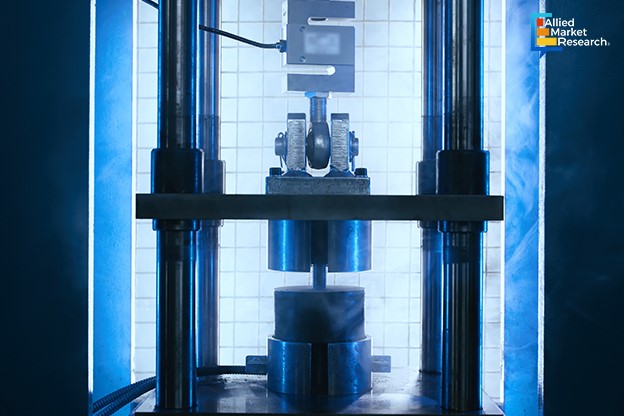

The field of rubber testing equipment involves a wide range of specialized instruments and tools created to evaluate the physical, mechanical, thermal, and chemical characteristics of rubber and elastomer materials. These instruments play an important role in assessing characteristics such as tensile strength, hardness, abrasion resistance, viscoelastic behavior, thermal stability, and more.

They are essential in quality control, research and development, and ensuring the reliability and compliance of rubber products in various industries, including automotive, aerospace, healthcare, and manufacturing. The common equipment used for rubber testing involves Mooney viscometers, moving dye rheometers, and rubber process analyzers. By product type, the rubber process analyzer category is anticipated to gain an absolute revenue growth of $0.2 billion by 2032.

Futuristic trends contributing to the expansion of the rubber testing equipment sector:

Robust demand for tires from the automotive industry:

The global rubber testing equipment industry has experienced growth, fueled by the rising prevalence of vehicles equipped with off-the-road tires (OTR), heavy truck tires, and light truck and passenger car tires. This expansion is attributed to the evolution of various tire testing methods, including endurance testing and radial run-out testing.

Regulations by the government:

The demand for rubber testing equipment continues to grow as governments and industry bodies implement more rigorous regulations and quality control measures. This trend is particularly notable in countries with a significant footprint in the rubber industry, including China, India, and the United States. The China rubber testing equipment industry is projected to portray a noteworthy CAGR of 7.90% by 2032. Simultaneously, India is estimated to hold second position with a 6.95% CAGR from 2023 to 2032.

As regulatory bodies impose more stringent standards on product quality and safety, industries that depend on rubber components are increasingly adopting advanced testing solutions. This shift is driving the demand for state-of-the-art rubber testing equipment that can meet and surpass regulatory requirements.

Integration of Industry 4.0 and automation:

The incorporation of automation and Industry 4.0 technologies is a significant factor fueling the rubber testing equipment market. Automated testing procedures not only improve efficiency but also ensure precision and consistency in outcomes. Industry 4.0 principles are reshaping testing equipment, turning it into intelligent systems that can perform real-time data analysis and predictive maintenance.

Role of advanced technologies in the transformation of the rubber testing equipment industry:

Advanced technologies are transforming the overview of rubber testing equipment. The adoption of the latest technologies boosts the efficiency and accuracy of equipment, which ultimately affects the final output. Here are the latest technological advancements in the industry:

AI and data analytics:

The fusion of data analytics and artificial intelligence (AI) is revolutionizing the methodology of rubber testing. AI algorithms meticulously analyze extensive datasets produced during testing, yielding valuable insights and predictions. This not only improves result accuracy but also plays a pivotal role in proactive decision-making for product development and quality assurance.

Non-destructive testing solutions:

These testing methods have become prominent in the rubber industry, enabling manufacturers to evaluate material quality without causing any damage. Techniques like ultrasound, infrared thermography, and eddy current testing are increasingly essential components of the rubber testing process.

· Latest materials testing:

The rubber testing equipment industry has evolved to tackle the challenges posed by testing modern materials. Advances in dynamic mechanical analysis (DMA) and rheometry allow for thorough evaluations of material properties, ensuring that rubber products meet the continually expanding performance expectations.

Key steps taken by top entities to boost their business profile

The global rubber testing equipment industry is highly competitive, and frontrunners are adopting advanced technologies to optimize their product reach and sustain the competition. For instance, Amade Technology, a reputable provider of rubber testing equipment, has recently introduced a new DIN abrasion tester featuring a dust suction function. This innovation is designed to offer the rubber industry more efficient, accurate, and safer abrasion testing solutions.

The DIN abrasion tester is a tool designed to replicate the abrasive effects on rubber products, including tires, hoses, belts, and materials used in footwear. This apparatus comprises a rotating drum enveloped in abrasive cloth and a specimen holder that applies a specified load and speed to press the rubber sample against the drum. The assessment involves measuring the material loss caused by abrasion, determined by weighing the sample before and after the test.

To sum up, the global rubber testing industry is expanding rapidly due to technological advancements and surging demand for quality control. However, the industry is projected to experience a substantial increase in the demand for portable and handheld testing devices, along with a growing preference for non-destructive testing methods. These adoptions will open new avenues for the sector in the upcoming era.

To gain an in-depth analysis of the rubber testing equipment industry, contact our experts today!

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training