Precision Tools in Eye Surgery: Understanding Ophthalmic Knives

27 May

2025

Highlights:

- Introduction

- Different types for different surgeries

- Sharp and safe

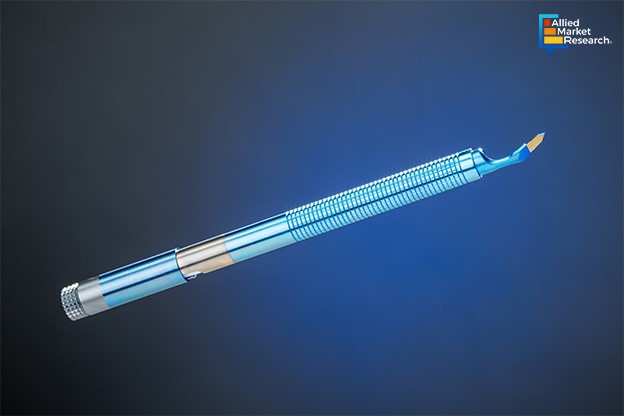

Ophthalmic knives are specialized tools used in eye surgeries that require extreme precision. These knives are designed to make clean, accurate incisions in delicate tissues of the eye. Their role is highly important in procedures such as cataract surgeries, glaucoma treatments, corneal transplants, and retinal operations. Surgeons depend on the quality and precision of these knives to carry out safe and successful interventions. The design, sharpness, and control offered by these instruments can influence surgical efficiency and patient recovery.

Various Types of Ophthalmic KnivesOphthalmic knives are not one-size-fits-all. There are many types, each designed for specific surgical needs. Among the common types are straight knives, slit knives, crescent knives, and micro vitreoretinal (MVR) knives. Straight knives are appreciated for their ability to be retracted using one hand, giving surgeons better control during delicate steps of a procedure. Slit knives are preferred for their shape and balance, helping to create accurate incisions in the cornea. Crescent knives are often used for creating scleral tunnels, while MVR knives are used in posterior segment surgeries. These variations ensure that surgeons can choose a knife that best suits the unique demands of each operation.

Disposable and Reusable OptionsOphthalmic knives are available in both reusable and disposable formats. Reusable knives are typically made from stainless steel and other durable materials, allowing them to be used multiple times after proper sterilization. However, this approach requires strict sterilization protocols to avoid the risk of cross-contamination. Over time, the blade may lose its sharpness, affecting performance.

Disposable knives, on the other hand, are designed for single-use applications. These knives offer the advantage of consistent sharpness and reduced infection risk. Surgeons can rely on the same level of blade performance each time, and there's no need to manage sterilization. The trade-off is higher recurring costs, but many surgical centers prefer the convenience and safety of disposable options. According to Allied Market Research, the ophthalmic knives industry accounted for $385.70 million in 2023 and is anticipated to reach a sum of $565.88 million by 2032, rising at a CAGR of 4.3% during 2024-2032.

Importance of Blade Sharpness and MaterialBlade sharpness is a key feature in ophthalmic knives. A sharper blade means less pressure is needed during the incision, which minimizes trauma to the eye tissue. This can lead to reduced inflammation and a quicker healing process. Some knives are treated with special coatings to maintain their sharpness during use. Others use advanced grinding techniques to create microscopically fine edges.

The materials used in the knife also matter. Surgical-grade stainless steel is commonly used due to its strength, corrosion resistance, and ability to hold a sharp edge. Some newer designs also include ceramic or diamond-coated blades to further enhance performance. The goal is always to maintain the precision needed for the microscale work involved in eye surgery.

Design Improvements for Better HandlingIn recent years, the design of ophthalmic knives has evolved to improve ergonomics and handling. Surgeons often work under a microscope and need tools that provide maximum control with minimal movement. Knives are now made with textured or contoured grips to reduce hand fatigue and allow finer manipulation.

Some knives include color-coded handles for easy identification during surgery. Others have safety features such as retractable blades to prevent accidental injury when the knife is not in use. These small details contribute to a smoother surgical experience and help surgeons focus on the procedure itself rather than on managing the tool.

Quality Standards and Regulatory FrameworksThe production and use of ophthalmic knives are governed by strict quality standards. These instruments are usually classified as surgical tools and must meet basic performance and safety requirements. Regulations require that manufacturers follow standardized processes to ensure the knives are sterile, sharp, and safe for use.

To meet these requirements, manufacturers perform routine inspections and quality checks during production. Each knife must pass tests for sharpness, cleanliness, and structural integrity before it reaches hospitals and surgical centers. Consistency is essential, as even minor defects in a blade could compromise a surgery.

Training and Surgeon FamiliarityUsing ophthalmic knives effectively depends on proper training and familiarity with the tools. Surgeons and surgical staff need to understand the properties of each knife type and know when and how to use them during a procedure. Training programs often include hands-on practice with different knife models to help professionals gain confidence.

Technicians and support staff also play a significant role in ensuring the correct knife is available and properly prepared for each surgery. They handle tasks such as opening sterile packaging, checking blade condition, and safely disposing of used instruments. A well-coordinated team can reduce the risk of surgical errors and improve patient outcomes.

Recent Activity in the Ophthalmic Instrument SectorThere has been noticeable activity in the ophthalmic surgical tools sector. Several companies are enhancing their portfolios by improving knife design, expanding manufacturing capabilities, and integrating more ergonomic features into their products. Product development is also focusing on reducing blade flex during incisions and improving tip precision for challenging eye conditions.

Changes in surgical technique and patient expectations have driven many of these innovations. Surgeons are seeking tools that allow for faster procedures with better recovery profiles. In response, developers are working on knives that offer better control and fewer complications during common surgeries like cataract removal.

Closing ThoughtsOphthalmic knives are an important component of modern eye surgery. Their design, sharpness, and reliability directly affect the success of procedures and the comfort of patients. With ongoing developments in blade materials, design ergonomics, and safety features, these tools are becoming more advanced and user-friendly. For hospitals and eye surgeons, knowing the types, materials, and quality of ophthalmic knives helps them choose the right tool for each surgery. Although there have been new improvements, the main goal is the same—better accuracy, safety, and results in eye operations.

For more information on the investment opportunities in the sector, contact our specialists here!

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training