Multi-Metal Aluminum Sandwich Panels To Witness Increased Demand From Aerospace And Automotive Sectors

14 Jul

2021

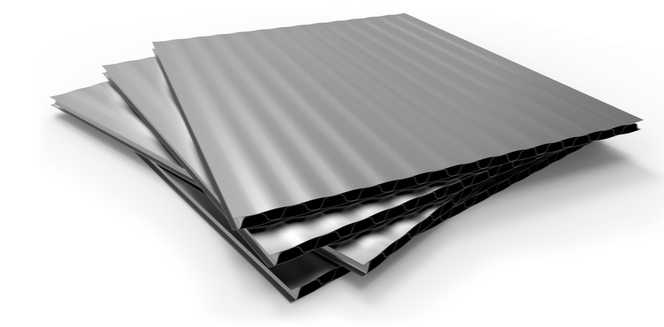

Sandwich panels with multi-metal aluminum have emerged as an essential building material in the construction industry. What’s more, other sectors such as aerospace, automotive, marine, and railway industries have recognized the potential of remarkable properties of multi-metal aluminum sandwich panels.

According to Allied Market Research, the multi-metal aluminum sandwich panels market is expected to reach $11.4 billion by 2027, registering a CAGR of 6.8% from 2020 to 2027. Surge in demand for fast and economic construction techniques and the growth of the construction industry in developing countries drive the growth of the market.

Although sandwich structures offer exceptional mechanical properties including stiffness and superior strength, these structures often fail to withstand low-velocity impact. However, sandwich panels with multi-metal aluminum help overcome the pitfalls of sandwich structures. Thus, the demand for these sandwich panels has increased in the automotive and aerospace sectors.

The industry of automotive is ever-changing and automakers constantly look for new, lightweight materials that can handle extreme pressure at affordable cost. This search ends at multi-metal aluminum sandwich panels. The use of these panels helps minimize complexity while reducing energy and water consumption.

Rise in investments and R&D activities in sandwich panels

Any panel is useful only if it could withstand hypervelocity impacts. Thus, a team of researchers tested honeycomb core sandwich panels filled with shear thickening fluid (STF). It was observed that using STF into shielding could reduce the damaged core and back-side facesheet perforation in case of hypervelocity impacts. Furthermore, STF showed rise in viscosity with increased shear rate that was well above the critical shear rate. In conclusion, the STF-filled panels showed less damaged compared to other panels such as PEG-filled panels.

Recently, ThermHex Waben GmbH, a German thermoplastic honeycomb core producer announced a €1 million capital investment for process optimizations and production expansion. The company has been producing polypropylene (PP) honeycomb core with PP/glass fiber skins. These panels were widely accepted in the market and demand in the automotive industry for a variety of applications. The panels offer reduced weight, minimum raw material usage, short cycle time, recyclability at an affordable cost. The company’s honeycomb cores are now used in automotive roofs for Ford and Volkswagen, doors, and swimming pools.

Request Sample Copy of this Report @ https://www.alliedmarketresearch.com/request-sample/11463Â Â Â

Increased popularity of honeycomb sandwich panels

Every creation of humans is inspired by nature, including the invention of the honeycomb structure. It offers greater strength in tension due to its two thin layers formed in a plate-like assembly. Honeycomb panels are now widely used in flat and slightly curved surfaces where high strength is needed.

Honeycomb sandwich panels witnessed higher demand in the aerospace industry for the manufacturing of rockets and aircraft due to their lightweight and affordable price. Now with the advent of multi-metal aluminum in sandwich panels opened new opportunities in the manufacturing of aircraft. Moreover, multi-metal aluminum sandwich panels with a core of expanded polystyrene, polyurethane, and glass wool have witnessed exponential growth in demand over the last few years.

There is no limit to innovation, especially when it comes to manufacturing new materials that offer exceptional strength. While multi-metal aluminum sandwich panels have opened new doors of opportunities in the automotive and aerospace industries, researchers have been experimenting with new materials as core to improve the performance of aluminum sandwich panels.

Koyel Ghosh

Author’s Bio- Koyel Ghosh is a blogger with a strong passion and enjoys writing in miscellaneous domains, as she believes it lets her explore a wide variety of niches. She has an innate interest in creativity and enjoys experimenting with different writing styles. A writer who never stops imagining, she has been serving the corporate industry for the last five years.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training