Innovation at 30,000 Feet: 3D Printing and Aerospace Technology

6 Jun

2016

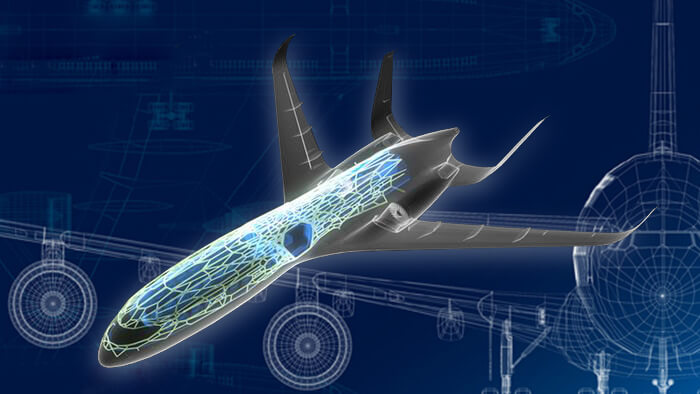

While technology has not quite mastered the art of dematerializing transporter used in "Star Trek," engineers have figured out how to reliably transmit an object from conceptual digital space into physical reality. Developments in 3D printing and forward-looking innovations in the aerospace industry enable computer modeling of sleek components to bring about a transformation in the aerodynamic sector. This partnership will have massive positive connotations for the future of airborne travel both in Earth's skies and beyond. This is possible due to the advent of technology that was not conceivable a scant decade ago.

Walls and WidgetsAdditive manufacturing is a style of 3D printing that "builds" a piece using a medium instead of carving it out. It has been very successful for companies such as McFarlane Aviation, according to the industry website 3Ders.com. In McFarlane’s sizable warehouse, crucial components, such as fuel nozzles and cabin-wall partitions, are custom-made for major airlines and airplane manufacturers. The additive manufacturing method offers unprecedented flexibility to the process, a true boon for the always-under-construction flight industry. Imagine the ability to print a beta-test model of cabin design for customer feedback without committing a fleets' worth of material contracts. With this one-off manufacturing method, it is a decidedly viable reality.

Printing-Up Efficient Fuel UseWith costs from passenger tickets to dimensional air freight calculated on the price of airplane fuel, getting the most out of every drop is understandably vital. Thanks to GE's inventive 3D-printed sensor housings, notes 3DPrint.com, airlines are getting a more detailed look than ever before at the performance of their engines. This data not only helps the current range of aviation engines to achieve peak performance, but also provides the future generation with better engine design options. This results in more efficient fuel use at every stage and hopefully lowered costs to pass on.

Seating Solutions On-The-GoThe problem with designing an airplane seat is that the idea of comfort varies from person to person. Stratasys Direct Manufacturing states that 3D printing may be the solution to aviation seat woes, both in design and turnover. The use of additive manufacturing to design prototype plane seating, armrests, and others increases their efficiency and creates a more durable framework. This method ensures high-quality airline-seating solution as well as aids airline companies to replace worn-out and broken components without disrupting their flight schedule.

What will the future hold for 3D-printed aerospace components? Provided that the facilities are large enough and teams perform sufficient testing, it is not inconceivable that an entire 3D printed plane may fly the skies in this generation. The key to making this high-flying dream a reality involves support and collaboration between the additive-manufacturing industry and airplane manufacturers, both notoriously secretive when it comes to proprietary knowledge. With such a bright future at stake and numerous steps already taken in the right direction, it may not be as steep a takeoff as a casual glance would

Rosy Behera

Author's Bio- Rosy Behera holds a bachelor’s degree in Electrical and Electronics Engineering and now she is a content writer by profession. She loves to portray her thoughts and ideas with a nice command of words. Grabbing an audience with her creative write-ups is one of her biggest assets so far. Apart from writing, she is a certified “Odisi” dancer and has done Gardharva in Drawing, Painting, and Arts. She always explores new things through travel and is a big foodie.

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training