Why Are Waste Management Companies and Healthcare Businesses Increasingly Investing in Nonwoven Filter Media?

29 May

2024

Key takeaways:

- Introduction

- Role of nonwoven filter media in urban waste management

- The rise of the industry in Asia-Pacific

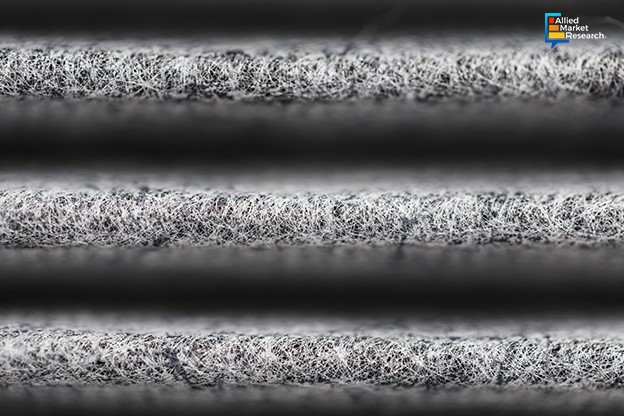

Nonwoven filter media are porous materials made from fibers that are designed specifically for air and liquid filtration. The fibers used to manufacture these filter media are bonded together using mechanical, chemical, or thermal processes to impart strength and flexibility. Typically, the mean flow pore (MFP) ratings of nonwoven filter media are between 1 and 500 microns, which makes them an ideal solution for several applications. For effective air purification purposes, these filters are used in HVAC systems, vacuum cleaners, exhaust hoods, and automobiles. On the other hand, end-use industries such as food processing and water treatment use them for liquid filtration of different fluids.

Nonwoven filter media for urban waste management applications

The rapid expansion of urban centers and the increasing pace of migration toward metropolitan cities have increased the volume of household and industrial waste in these cities significantly. While household waste is mostly unsegregated, many industries directly release the effluents into the natural water bodies. Overall environmental pollution in urban towns and cities has increased massively due to these practices. To overcome these challenges, local authorities in cities across the globe have started employing certain innovative methodologies and technologies that will ultimately reduce air and water pollution.

Nonwoven filter media has become an effective and popular solution in urban waste management owing to some of its inherent advantages. Firstly, these filter media have anti-microbial properties; meaning, along with filtration, they also inhibit the growth of micro-organisms, thereby purifying the water simultaneously. Secondly, they are designed in such a way that they not only filter out solid particles from the liquid but also separate two different liquids with distinct viscosities like water and oil. Hence, these filter media have now become vital components of filtration systems that are developed for maintaining the quality and purity of liquids.

In January 2024, Ahlstrom, a leading innovative fiber solutions developer, announced the launch of water filter media with sustainable fibers. The new filtration system has been specifically designed for efficient removal of particulate matter in pre-filtration applications. The company has already launched two filter media product ranges viz., Ahlstrom Disruptor® and Hollytex®. Ahlstrom released a statement after the launch saying that this new product can be used as a standalone material in filtration processes or can complement the other two products for better results. All these products are designed for both domestic and industrial purposes.

The Asia-Pacific region to dominate the industry

In the past few years, the nonwoven filter media industry has experienced massive growth across the globe, particularly in the Asia-Pacific region. The increasing pace of urbanization and industrialization in the major economies of India and China has led to a growth in demand for these filters, thus helping the landscape flourish in this province. The China nonwoven filter media sector is, in fact, projected to have the fastest growth rate and surge ahead at a CAGR of 7.2% in the 2023-2032 period.

Another important factor that has increased the revenue share of the industry in the Asia-Pacific region is the growing expanse of its healthcare sector and the corresponding rise in the demand for these filter media. Over the past few years, the demand for nonwoven filter media has increased massively in medical industries as they form an essential component of surgical masks, medical gowns, respirators, and other such accessories. Due to their unique structure and the ability to act against viruses and bacteria, they are also used in manufacturing medical devices and IV filters.

Also, in recent times, with advancements in nanotechnology, several filter media manufacturers have developed water-resistant and breathable fibers that are used to manufacture filters for wound dressings. These filters have the ability to withstand sterilization and their anti-corrosion properties can offer stability even against the harshest of chemicals.

To sum it up, the various advantages offered by nonwoven filter media have made them a popular choice for urban waste management systems. Furthermore, their anti-microbial and water-resistant features have increased their demand in the healthcare sector as an effective wound dressing material. The innovative products launched by key companies are predicted to open new avenues of growth in the landscape in the coming period.

For tips and suggestions on how businesses can increase their revenue share in the industry, feel free to contact us.

Akhilesh Prabhugaonkar

Author's Bio- Akhilesh Prabhugaonkar holds a bachelor’s degree in Electronics Engineering from the reputed Vishwakarma Institute of Technology. He has a special interest in the fields of forensics, world history, international relations and foreign policy, sports, agriculture, astronomy, security, and oceanography. An ardent bibliophile and melophile, Akhilesh loves to write on topics of his interest and various other societal issues. This love for writing made him enter the professional world of content writing and pursue his career in this direction.

Cold Rolling Steel Coils: Understanding the Role of This New Innovation in Reshaping the Construction and Automotive Sectors

Avenue: Entire Library membership of Allied Market Research Reports at your disposal

- Avenue is an innovative subscription-based online report database.

- Avail an online access to the entire library of syndicated reports on more than 2,000 niche industries and company profiles on more than 12,000 firms across 11 domains.

- A cost-effective model tailored for entrepreneurs, investors, and students & researchers at universities.

- Request customizations, suggest new reports, and avail analyst support as per your requirements.

- Get an access to the library of reports at any time from any device and anywhere.

Related Post

-

How are Submarine Cables Transforming Global Connectivity with Enhanced User Experience?

-

Endoscopy Procedures: Transformations in Techniques and Applications

-

AI-Powered Video Analytics: How the Product Actually Works for enterprises

-

Painting Robots: Transforming Precision Coating and Creative Applications

-

Innovations in Pharmacovigilance Systems Advancing Patient Safety

-

Understanding Edge Security: Keeping Data Safe Near the Source

-

Exploring the Use and Advancements of 3D Laser Scanners in Professional Applications

-

Reinforcing Industrial Controls with Smarter Tools and Training